Roartis IQ-BOND 2472-LV

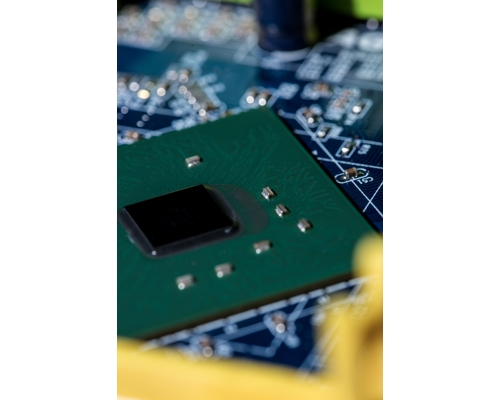

IQ-BOND 2472-LV is a fast-cure, solvent-free, one-component, pre-mixed, thermoset epoxy based adhesive, developed for underfill applications, especially for CSP and/or BGA applications. It is the lower viscosity version of IQ-BOND 2472.

The rheology of IQ-BOND 2472-LV, in combination with its low thermal expansion, make it an ideal solution for high reliability applications in harsh environments.

IQ-BOND 2472-LV was especially designed to combine high filler loading to minimize the thermal expansion, combined with low viscosity and low thyxotropy. These properties make IQ-BOND 2472-LV an ideal underfill solution for applications where the thermal expansion (CTE) of the underfill needs to be minimized. To facilitate and accelerate the underfilling-flow process, it can be considered to heat the substrate to about 80°C during the dispensing process.

The chemistry of IQ-BOND 2472-LV has been selected to resist temperatures over 150°C for continuous operation.

The special selected filler type allows a high filler loading, assuring low CTE (coefficient of thermal expansion), which improves thermal cycling performance for applications in harsh environments.

IQ-BOND 2472-LV can also be used for bonding applications where thin bondlines are required, and will provide good adhesion to materials such as glass, ferrite, aluminum, FR4, ceramic and steel.

Although IQ-BOND 2472-LV is a pre-mixed, one-component epoxy system, the chemistry is stable at moderate storage temperatures (fridge < 5°C). The potlife of IQ-BOND 2472-LV is more than 5 days at room temperature. To improve the storage stability of IQ-BOND 2472-LV, and specifically to avoid possible risk of filler sedimentation during storage, it can be considered to store IQ-BOND 2472-LV at temperatures < -20°C.

When fully cured, IQ-BOND 2472-LV is resistant to moisture, cleaning agents and dilute acids and bases. IQ-BOND 2472-LV is a solvent-free, 100% solids material.

For cleaning un-cured IQ-BOND 2472-LV from substrates, dispensing equipment, or other tools, the use of IQ-CLEANER 9500 is recommended.

Product Properties:

- Appearance: Milky liquid (before cure) → Beige solid (after cure)

- Chemistry: Epoxy

- Odor: Faint

- Mix-Ratio: Not Applicable – pre-mixed single component adhesive

- Hegmann Fineness: < 40 μm

- Viscosity at 25°C: ~ 1.700 mPa.s (Brookfield RVII, CP51 at 10 rpm)

- Viscosity at 70°C: ~ 250 mPa.s (Brookfield RVII, CP51 at 10 rpm)

- Filler content (wgt%): ~ 48%

- Tg: ~ 105°C

- CTE1: ~ 35 - 40 ppm

- Shore hardness: ~ 90 shore D

- Service temperature: -55°C to 150°C

- Die shear strength: > 200 kg/cm²

- Density: ~ 1,47 gr/cm³

-

Cure Speed:

- 3 minutes @ 150°C

- 20 minutes @ 120°C

- 60 minutes @ 100°C

For good mechanical strength, cure according above conditions is recommended. The final bond strength will depend on the residence time at the given cure temperature. Typically, a higher curing temperature, as well as a longer cure time will result in higher adhesion strength, and improved polymer crosslinking. In any case, it’s recommended to consider a post-cure of about 1 hour at temperature similar or above the maximum operation temperature to have optimum properties, and elevated Tg.