Novi proizvodi

-

Ekra - SERIO 6000 - Autonomy to Infinity

-

First fully automatic printer worldwide

-

Automated Paste Exchange System

-

New Print Head

-

Intelligent Paste Dispense System

-

Automatic Stencil Loader

-

-

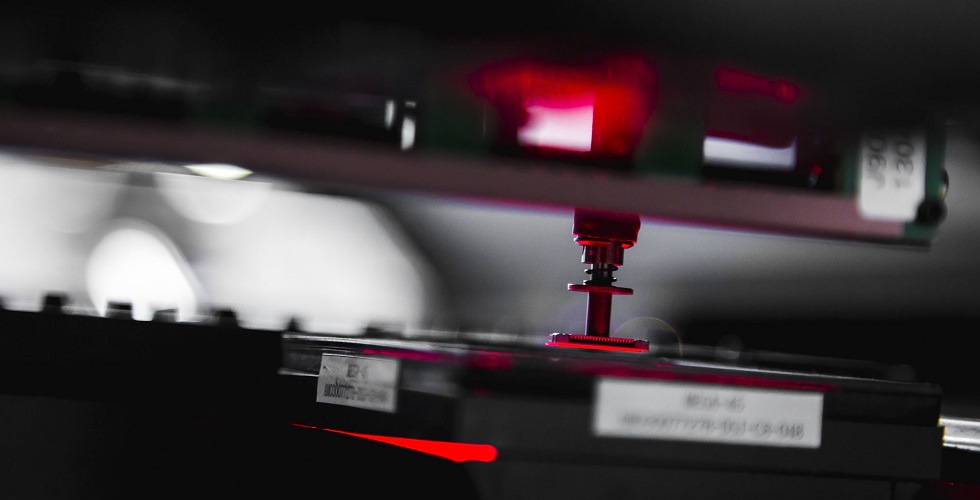

Hanwha - SM485P

- 1 Gantry x 4/Head

- Placement speed: 12,000 CPH Chip/ 4,500 CPH Odd-type/Insert components (Optimum)

- Placement accuracy: ±50㎛ Cpk≥1.0 (0603 Chip)

- Components: 0603 ~ □22mm, H32mm (S-Fix); ~ □55mm, L150mmx25mm, H32mm (Fix Cam.)

- PCB Size: Max. 460 x 400 (Standard)

- Max. 610 x 460 (Option)

- Force control (Option): 0.5N~ 50N (Approx. 50g~5kg)

-

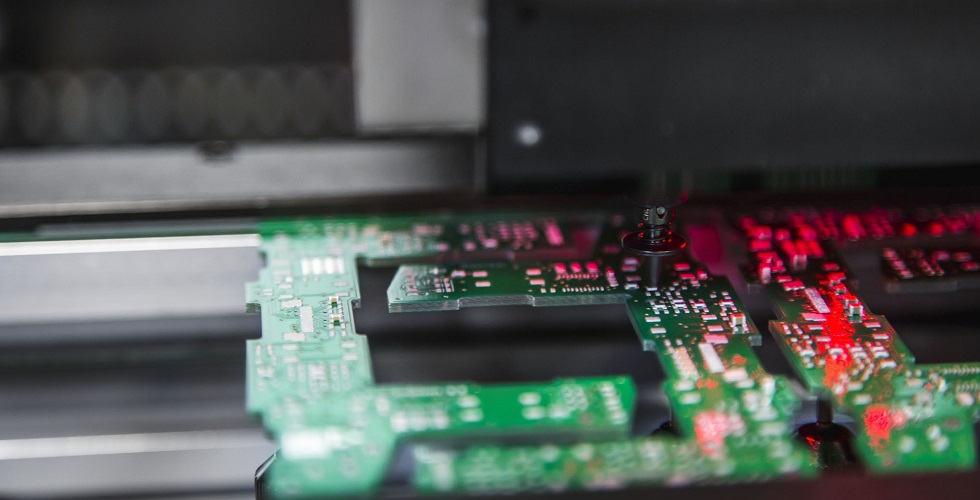

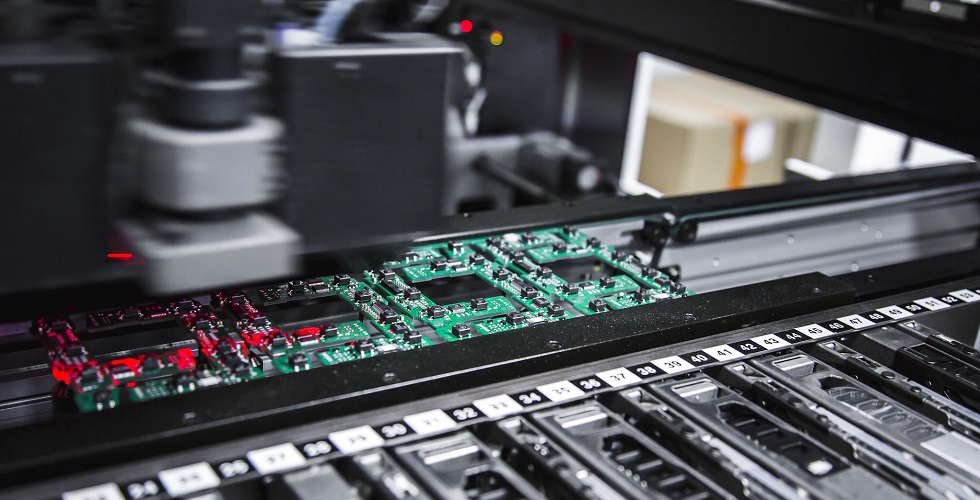

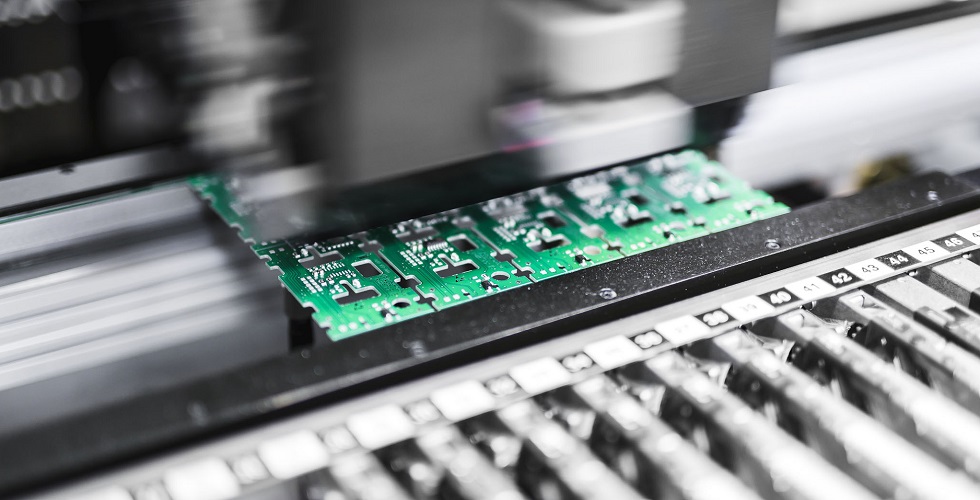

Hanwha - Decan S1

- 03015 ready and highly flexible with wide component range up to 75 mm in lenght

- Faster loading pcb time and long board option up to 1500 mm in length

- Single gantry with 10 spindlles high accuracy ± 28 μm Chip and ± 35 μm IC

- New fly mega pixel camera system up to 0,3 mm lead pitch

- Machine suitable for small quantity batch production due to frequent model change

-

SEHO - LeanSelect

Flexible, short cycle times and consistently designed according to Lean Equipment Design Guidelines

- Ideally suited for up-to-date manufacturing islands

- High flexibility and productivity

- High production rate with up to five carriers in process at the time

- High precision fluxer system and reproducible preheat process

-

Totech - DRY TOWER - AUTOMATED SMD STORAGE SYSTEM

- Smart factory component storage & Material Logistics

- Flexible reel size and volume

- Chaotic optimised on space

- Dynamic MSL control

- Automatic Reset (<1%RH, 60C)

- Scalable

- Connected

- High availability

-

LPKF - ProtoLaser H4

Tabletop System for Fast PCB Processing

-

Combines the advantages of mechanical drilling of thick substrates including multilayers with

extremely fast, contactless, laser surface processing in one tabletop system. - Quick surface processing on all common circuit board materials

- Exact geometries thanks to contactless, scanner-based process

- Precise drilling and routing of even thick substrates using mechanical drilling.

- Compact and safe tabletop system: lab-ready, class 1 laser

- Easy operation using intelligent, intuitive system software LPKF CircuitPro RP

-

Combines the advantages of mechanical drilling of thick substrates including multilayers with

-

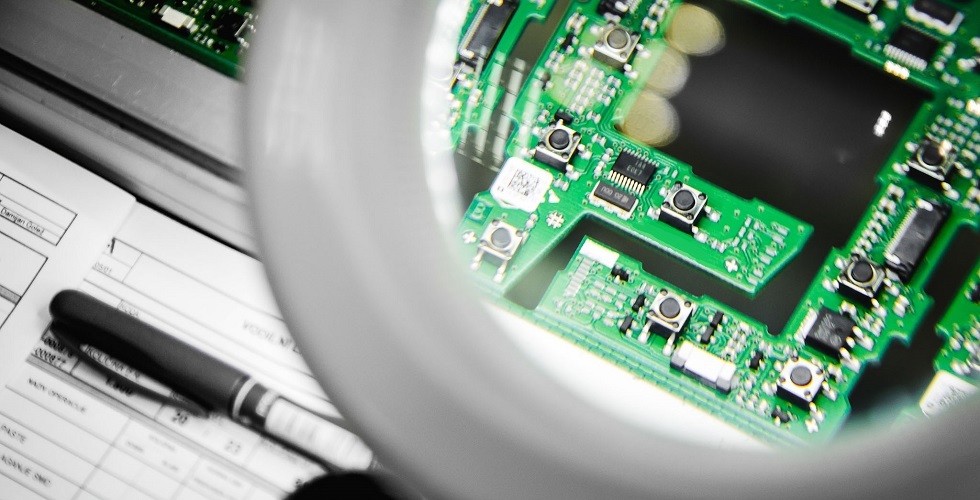

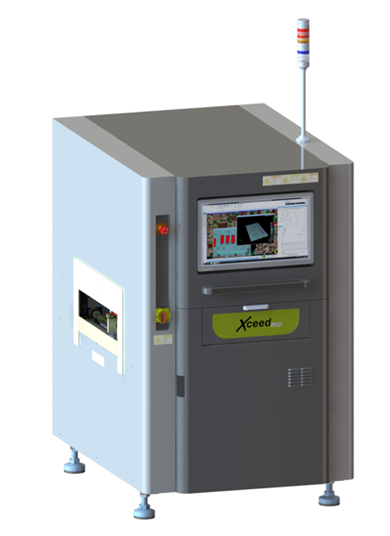

PARMI - Xceed BSI

- High speed bottom side inspection 3D AOI platform

- Shadow free dual laser measurement method

- Mayor application in THT inspection

- Easy to use simple & intuitive GUI

- Extremely low false call and escape rate by true 3D shape

-

PVA - SIGMA

Benchtop Coating/Dispensing System

- 5-inch touch interface with Wi-Fi connectivity

- Offline G-code numerical control programming

- Enclosed work area with safety interlock

- Single or dual valve mounting positions

- Standard jig plate mounting surface