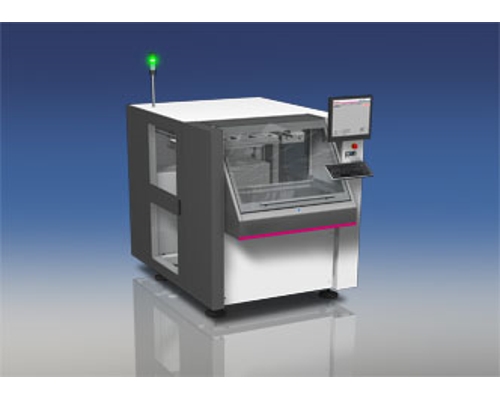

DIVISIO 2000 Ergo

The DIVISIO 2000 Ergo is a semi-automatic system for stressfree depaneling of PCBs. By positioning the routing axis either above or below the electrically driven rotary table, the system has the flexibility to represent a verified production process.

It can therefore be used without any restrictions as back-up for the inline production. The X- and the Y-axes are both equipped with highly dynamic linear motor technology, the Z-axis is servo-driven. Already existing product carrier adapters can easily be used with this machine.

The vacuum system is optimized with the help of the Tornado-Effect. The system offers a cost-efficient solution for customers who wish to depanel stress-free but who do not produce such a high volume to justify the acquisition of an inline machine.

Features:

- X- and Y-axis with high-end linear motors

- Z-axis servo-motor-driven

- Rotary-table with two working areas

- Touch screen monitor

- HMI offers comfortable operation

- Ionization unit

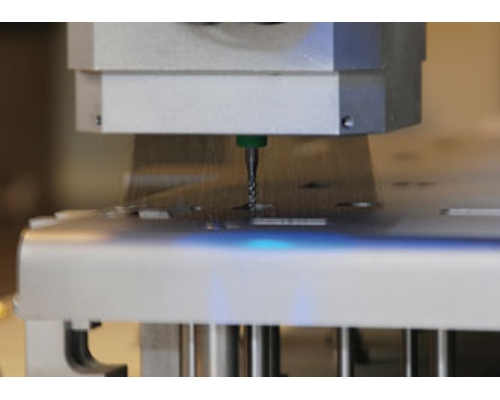

- Automatic tool change with 2 routers per magazine

-

Complete tool management

- Breakage control

- Length verification

- Diameter check

- Life span monitoring

- Dynamic utilization of full router bit

Options:

- Routing module (from top / bottom) or sawing unit (from top)

- Program creation with ASYCAM CAD import

- Camera system

- Vacuum exhaust system

- Manual suction unit

- Adapter technology

- Upgrade of Automated Router bit change to 8 bits

- Traceability function

- Database Interface