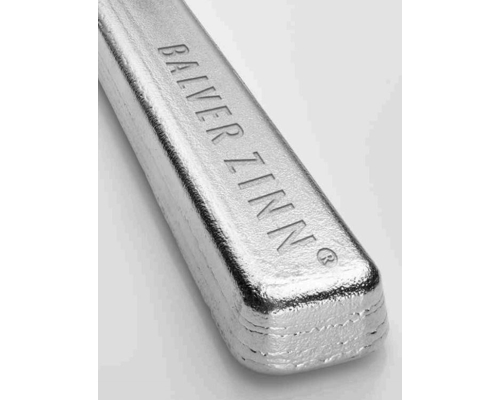

Balver Zinn Lead free SN100CV

BALVER ZINN SOLDER SN100CV® (SnBi1.5Cu0.7NiGe) is a patented version of the worldwide well-known solder SN100C® with the addition of bismuth. SN100CV® is like SN100C® a nickel-stabilized tin-copper solder, containing a small amount of germanium to reduce oxidation.

The tensile strength of SN100CV® is approx. 30% higher compared to SN100C® and reaches even higher values than SAC305 because of the presence of bismuth. SN100CV® is a silver- and lead-free* solder for high reliability applications.

Compared with SN100C®, SN100CV® causes less copper dissolution that allows very stable processes and easy solder bath management.

BALVER ZINN SOLDER SN100CV® is an invention of NIHON SUPERIOR® with patent number JP 5872114.

BALVER ZINN is worldwide the first licensee and offers SN100CV® as bar, cored wire and solder paste.

*BALVER ZINN SOLDER SN100CV® does not contain hazardous substances beyond the limits prescribed by EU Directive 2011/65/EU (“RoHS II”)

General Process Information

- With copper content of more than 0.85%, significantly more soldering defects occur (bridging!). To avoid these, BALVER ZINN offers complimentary solder bath analyses. When soldering any printed circuit board - except those with a nickel/gold finish – SN100CVe® should be used for bath top-up to ensure constant process conditions.

- The copper tin crystals precipitating at a copper content of more than 0.9% (intermetallic joints), have a grinding effect and, due to the low density of the solder, accumulate on the bottom of the solder bath. They cannot be removed from the solder surface by a perforated spoon.

- Due to its special stabilization, SN100CV® affects pots and pumps far less than tin silver copper solders. In special cases SN100C can be used in soldering machines with plain stainless steel pots. In order to reduce solder losses as dross, nitrogen protection is recommended.

- BALVER ZINN conducts complimentary, regular solder bath analyses to determine the customer-specific bath top-up schedule and avoid problems caused by excessive impurities.

Process Conditions for Wave Soldering

- Solder bath temperature 260 – 270°C. Please note that it is not the solder temperature but the temperature measured on the components, which determines the level of thermal stress subjected to the component.

- Before entering the wave, the printed circuit boards should be about 10 – 20°C warmer than for tin-lead applications (Sn63Pb37). 110 – 135°C, measured on the top surface, are usual conditions. Here, the old rule applies: “Do not try to use the wave for preheating”!

- The contact time in the wave has to be increased due to slower wetting in comparison with tin lead (Sn63Pb37).