VEGO Loading systems

Loading systems automatically feeds PCB's loaded on the magazine rack to the downstream process line using a pusher.

Magazine loader with a platform for one magazine - VEGO Dynamic AES 01

The unit uses an electrically driven pusher to slide the PCB’s out of the magazine and onto the receiving conveyor of the following unit. The magazines are changed manually.

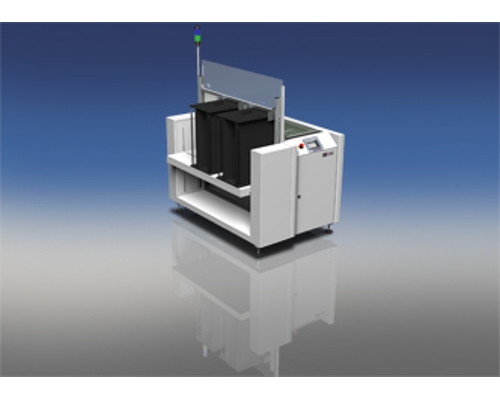

Magazine loader with a platform for two magazines - VEGO Dynamic AES 03D

The loading station AES 03D is used to automatically feedPCBs into an SMT-production line or into individual processmachines e.g. stencil printers, pick and place systems, refl owovens or test systems. The PCBs are taken out of the magazine with an extractormechanism and pulled onto the handover conveyor. The handoverconveyor moves sideways on an integrated shuttle to thehandover position and the PCB is subsequently handed over. The system is characterized by its compact and robustconstruction and has been designed according to the latestmachine guidelines and safety standards. The open magazinetable provides easy access to the magazines. Magazine exchangeduring running operation ensured continuous loading.The integrated shuttle mechanism means that the system caneasily switch between different magazine types and handoverpositions within seconds.

Magazine loader with magazine buffer and automatic magazine change - VEGO Dynamic AES 04

The unit consists of a loading and an unloading conveyor for magazines, a lifting axle with a magazine platform, a transfer conveyer to the following unit and an electrically driven pusher. The input conveyor is situated directly below the output conveyor. The magazines are loaded onto the lower conveyor and transported into position on the magazine platform. From this position the PCB’s are extracted. The empty magazine is then transported back over the upper conveyor and stored until manually removed.

Destacker with buffer for PCB packages - VEGO Dynamic LLB01

The logistics loader LLB 01 is used to load marking stations or SMT production lines with bare PCBs. It combines a buffer station for PCB batches and a separator station in one unit. The system is designed for correctly sorted separation of the PCB batches according to the FIFO principle. They are stored mechanically isolated from each other until the separation process. This prevents the possibility that individual circuit boards of various charges may be mixed up. The PCB packages are manually inserted into the system and buffered. Then they are fed to the separator station. During the separation process, the stack is processed from the top down. Hence the separation process is independent from the stack weight, making it very gently for the product.

PCB destacker - VEGO Dynamic LSB 03

The LSB 03 is used to load bare boards for printing or marking into SMT production lines. The PCB stack is manually loaded into the machine and the individual PCBs are handed over to the downstream system on a transfer conveyor. The stack is processed from above which ensures gentle separation of the PCBs. The machine can be equipped with various methods of separation depending on the type of PCB used.