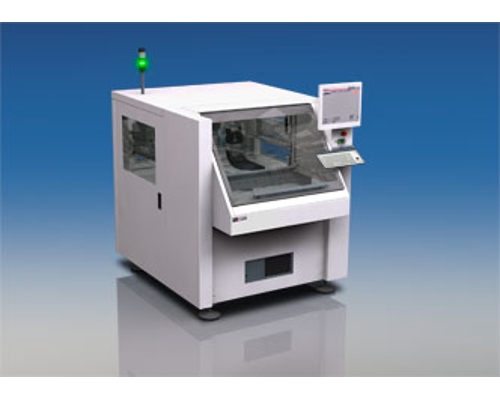

DIVISIO 2000 Ergo Base

The DIVISIO 2000 Ergo Base is the first step into the stress-free and automatic depaneling of PCBs. It represents a very costefficient solution for the medium-size production volume and product mix.

Due to its flexibility it is also the ideal basis for prototyping, the production of small lots and as back-up for the inline production. The dynamic routing axis is fixed above the electrically-driven rotary table.

This rotary table guarantees short cycle times and a high repeatability. The x- and y-axes work with high-end dynamic linear motor technology, the z-axis is servo-driven. Already existing product carrier adapters can easily be used with the DIVISIO 2000 Ergo Base. The vacuum system is optimized by using the proprietary Tornado-Effect.

Features:

- X- and Y-axis with high-end linear motors

- Servo-driven Z-axis

- Electrically-driven rotary table

- HMI offers comfortable operation

- Ionization unit

- Manual tool change

-

Complete tool management

- Breakage control

- Length verification

- Diameter check

- Life span monitoring

- dynamic utilization of full router bit

Options:

- Program creation with ASYCAM CAD import

- Camera system

- Vacuum exhaust system

- Integrated handheld suction

-

Adapter technology

- Product-specific adapters

- flexible adapter technology

- Adapter coding for up to 255 adapters