Roartis IQ-BOND 2409-LV

IQ-BOND 2409-LV is a solvent-free, one-component, pre-mixed, thermoset epoxy based adhesive, developed for applications where fast cure is required for short cycle times. It’s the lower viscosity version of IQ-BOND 2409.

The chemistry of IQ-BOND 2409-LV has been selected to resist temperatures over 200°C for short periods of time, and has been used in lead-free solder processes with peak temperatures as high as 270°C.

Unlike many other single-component adhesives, characterized by a short potlife, IQ-BOND 2409-LV has a very long potlife of > 1 week at room temperature.

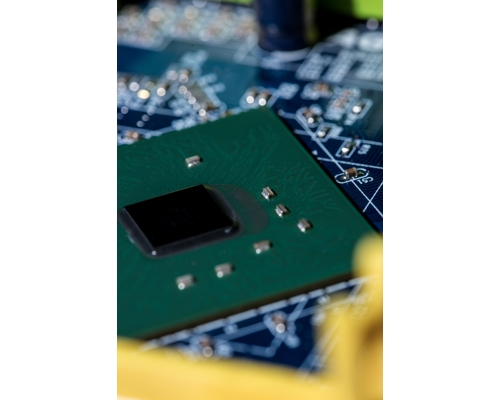

IQ-BOND 2409-LV was especially designed to assure good flow in small gaps, even at moderate temperatures. To facilitate and accelerate the underfilling process, it can be considered to heat the substrate and/or the IQ-BOND 2409-LV to about 50 – 60 °C.

When fully cured, IQ-BOND 2409-LV is resistant to moisture, cleaning agents and dilute acids and bases. Also it exhibits very good high thermal resistance, for example typical SnPb-, as well as lead-free soldering processes.

IQ-BOND 2409-LV is a solvent-free, 100% solids material.

For cleaning un-cured IQ-BOND 2409-LV from stencils, screens, squeegee, or other equipment, the use of IQ-CLEANER 9500 is recommended.

Product properties:

- Appearance: Black

- Chemistry: Epoxy

- Odor: Faint

- Mix-Ratio: Not Applicable – pre-mixed single component adhesive

- Fineness: < 10 μm

- Viscosity: 4.000 mPa.s (Brookfield RVII-CP51, 25°C at 5 rpm)

- Density: +/- 1,1 gr/cc

- Shore Hardness: ~ 85 D

- Tg: ~ 110°C

- CTE1: ~ 60 ppm

- CTE2: ~ 200 ppm

- Density: ~ 1,15 gr/ml

-

Cure Speed:

- 30 “ @ 175°C

- 2 – 3 minutes 150°C

- 5 minutes 120°C

For good mechanical strength, cure according above conditions is recommended, and a minimum of 100°C required. The final bond strength will depend on the residence time at the given cure temperature. Typically, a higher curing temperature, as well as a longer cure time will result in higher adhesion strength, and improved polymer crosslinking.